Newly Arrival Ceiling Insulation - Hydroxypropyl Methylcellulose HPMC – Beihua

Newly Arrival Ceiling Insulation - Hydroxypropyl Methylcellulose HPMC – Beihua Detail:

In building materials, it is used as a water-retaining agent and retarder for cement sludge with pumpability. It can be used as a binder in plaster, gypsum, inverted powder or other building materials to improve spreadability and prolong operation time. It can be used as an agent for sticking bricks, tiles, marbles, plastic decorations, and bonding intensifiers. It can also reduce the amount of cement. The water retention of HPMC prevents the slurry from cracking due to drying too fast after coating, and enhances the strength after hardening.

In addition, it is used as thickener, stability, emulsifier, excipient, water retention in the production of other petrochemicals, coatings, building materials, paint removers, agricultural chemicals, inks, textile printing and dyeing, ceramics, papermaking, and cosmetic brands. Agent, film-forming agent, etc.

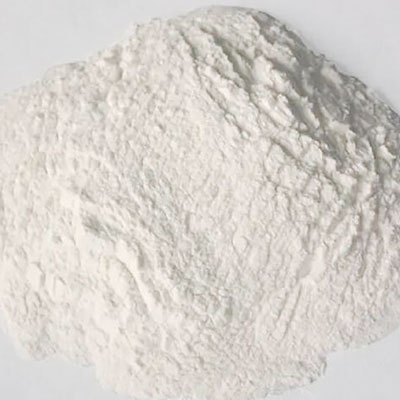

1. Appearance: white or almost white powder, odorless and tasteless.

2. Granularity: 10 mesh pass rate is greater than 98.5%; 80 mesh pass rate is greater than 100%.

3. Carbonization temperature: 280-300℃.

4. Room density: 0.25-0.7G/CM3 (usually about 0.5G/CM3), the specific gravity is 1.26-1.31.

5. Discoloration temperature: 190-200℃.

6. Natural temperature: about 360℃.

Production Method

The refined cotton cellulose is treated with lye at 35-40°C for half an hour, squeezed, the cellulose is crushed, and properly aged at 35°C, so that the obtained alkali fiber average degree of polymerization is within the required range. Put the alkali fiber into the etherification kettle, add propylene oxide and methyl chloride successively, and etherify at 50-80℃ for 5h, the maximum pressure is about 1.8MPa. Then add proper amount of hydrochloric acid and oxalic acid to wash materials in hot water at 90°C to increase the volume. Dehydrate with a centrifuge. Wash to neutral. When the water content in the material is less than 60%, dry it with a stream of hot air at 130℃ to less than 5%. Finally, it is crushed through a 20-mesh sieve to obtain the finished product.

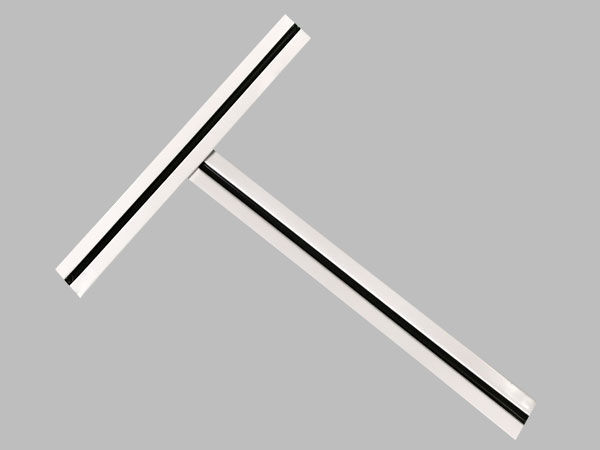

Product detail pictures:

Related Product Guide:

No matter new customer or old customer, We believe in long term and trusted relationship for Newly Arrival Ceiling Insulation - Hydroxypropyl Methylcellulose HPMC – Beihua , The product will supply to all over the world, such as: Angola, Croatia, Poland, Our staffs are rich in experience and trained strictly, with professional knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to provide the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we will develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.