1. Elastic line: According to the ceiling design elevation, the elastic ceiling line is used as the standard line for installation.

2. Installing the boom: Determine the position of the boom according to the requirements of the construction drawings, installing the built-in parts (angle iron) of the boom, and brush with anti-rust paint. The boom is made of steel bars with a diameter of Φ8, and the distance between the lifting points is 900-1200mm. During installation, the upper end is welded with the embedded part, and the lower end is connected with the hanger after threading. The exposed length of the installed boom end is not less than 3mm.

3. Installing the main keel: C38 keel is generally used, and the distance between the main keels of the ceiling is 900~1200mm. When installing the main keel, connect the main keel hanger to the main keel, tighten the screws, and lift the ceiling by 1/200 as required, and check the flatness of the keel at any time. The main keels in the room are arranged along the long direction of the lamps, and attention should be paid to avoid the position of the lamps; the main keels in the corridor are arranged along the short direction of the corridor.

4. Installation of secondary keel: The matching secondary keel is made of painted T-shaped keel, and the spacing is the same as the horizontal specification of the board. The secondary keel is hung on the large keel through a pendant.

5. Installation of side keel: L-shaped side keel is used, and the wall is fixed with plastic expansion pipe self-tapping screws, and the fixed distance is 200mm.

6. Concealed inspection: After the completion of hydropower installation, water test, and suppression, the keel should be concealed inspection, and the next process can be entered only after passing the test.

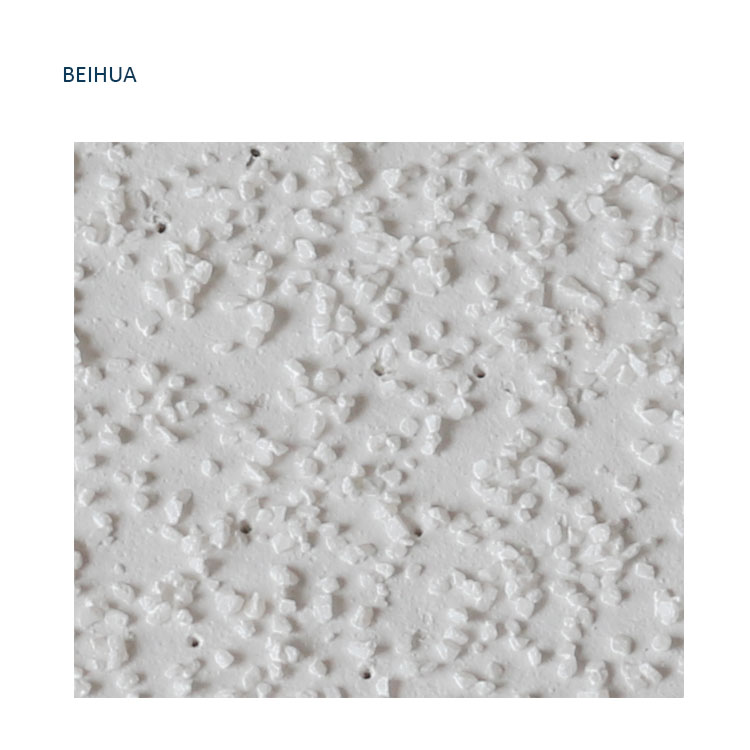

7. Attaching decorative panel: The mineral fiber ceiling board adopts approved specifications, and the exposed keel mineral fiber ceiling board can be directly placed on the T-shaped paint keel. The small keel that is installed with the board and installed, the operator must wear white gloves during installation to prevent contamination.

8.The following documents and records should be checked during the acceptance of the ceiling project. Construction drawings, design instructions and other design documents of suspended ceiling projects; product qualification certificates, performance test reports, site acceptance records and re-inspection reports of materials; concealed project acceptance records; construction records.

Post time: Mar-20-2024