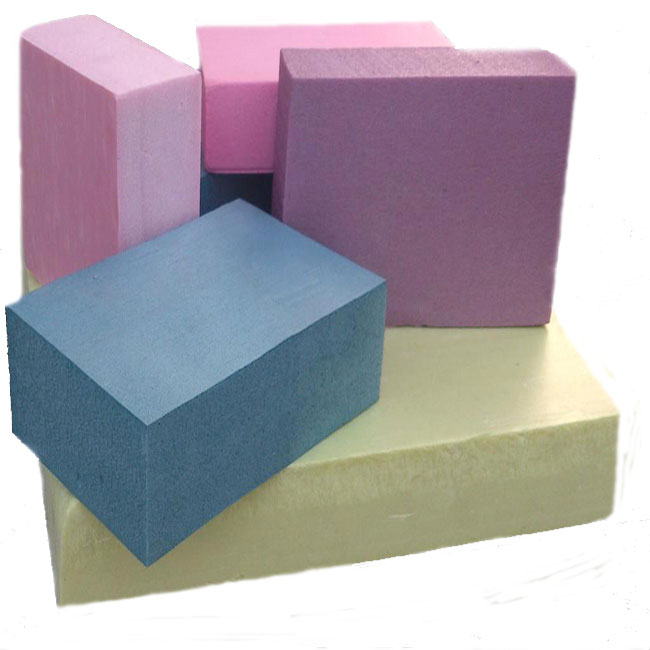

XPS insulation board is a rigid foamed plastic board made of polystyrene resin as raw material plus other raw materials and polymers, heated and mixed and injected with catalyst at the same time, and then extruded and molded. Its scientific name is extruded polystyrene foam (XPS) for heat insulation. XPS has a perfect closed-cell honeycomb structure, which allows XPS board to have very low water absorption (almost no water absorption) and low thermal conductivity. , High compression resistance, anti-aging (almost no aging decomposition phenomenon in normal use).The XPS board has a dense surface layer and a closed-cell structure inner layer. Its thermal conductivity is much lower than EPS of the same thickness, so it has better thermal insulation performance than EPS.

For the same building exterior wall, xps board thickness can be smaller than other types of insulation materials; due to the closed-cell structure of the inner layer. Therefore, it has good moisture resistance, and can still maintain good thermal insulation performance in a humid environment; it is suitable for buildings with special requirements for thermal insulation such as cold storage, and can also be used for buildings with brick or stone exterior wall facing materials.

Rigid polyurethane board has low thermal conductivity and good thermal performance. When the bulk density of rigid polyurethane is 35~40kg/m3, the thermal conductivity is only 0.018g~0.023w/(m·k), which is about half of EPS, which is the lowest thermal conductivity of all insulation materials. The rigid polyurethane board is moisture-proof and waterproof. The closed cell rate of rigid polyurethane is above 90%, which is a hydrophobic material, which will not increase the thermal conductivity due to moisture absorption, and the wall will not seep water.

Compared with other insulating materials, polyurethane rigid foam has the best thermal insulation performance. Therefore, thinner polyurethane sandwich panels can meet the relevant regulations on building energy consumption limits, which allows the use of thinner panels during construction, saving building space; stable quality and high production efficiency. In the case of a sharp increase in demand, the factory production line of polyurethane sandwich panels not only facilitates quality control, but also brings good economy and competitiveness.

Post time: Jun-29-2021