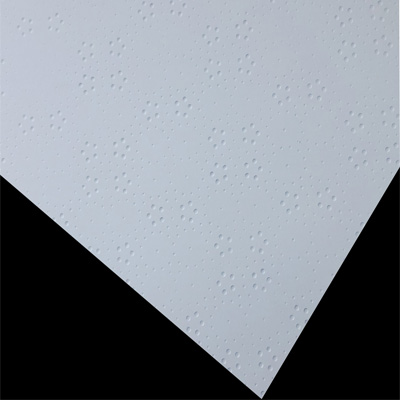

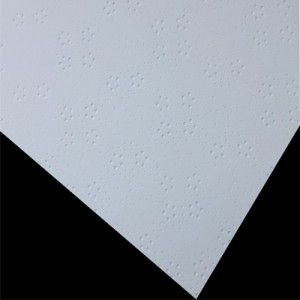

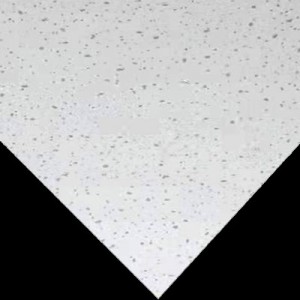

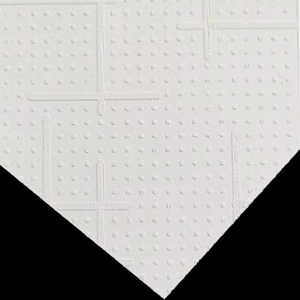

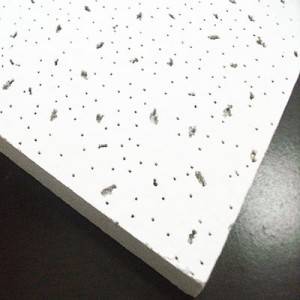

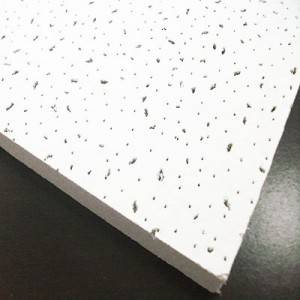

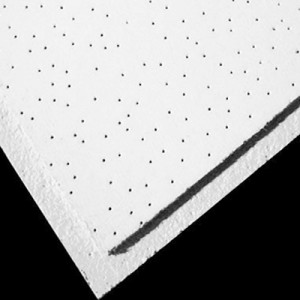

Decorative Ceiling Tiles Fireproof Calcium Silicate Ceiling Board

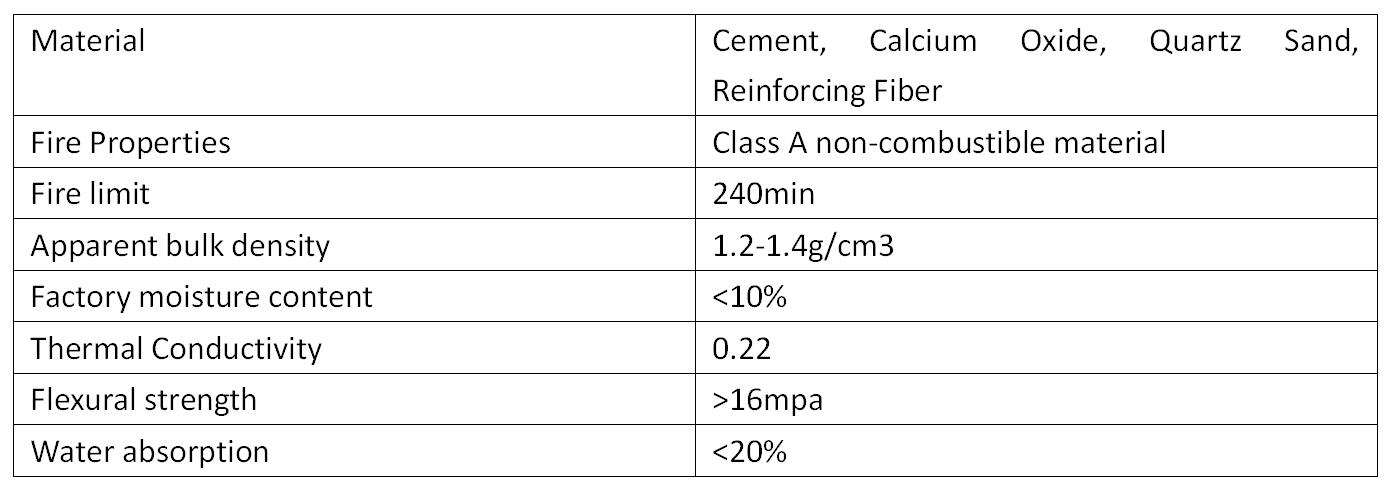

Calcium silicate board is a new type of environmentally friendly building material in recent years. In addition to the functions of traditional gypsum board, it also has the advantages of superior fire resistance, moisture resistance and long service life. It is widely used in ceilings and partition walls of industrial, commercial buildings, home decoration, furniture lining board, billboard lining board, warehouse shed board, network floor and tunnel wall board for indoor projects. Fiber-reinforced calcium silicate board is a new type of lightweight board that is mainly made of calcium materials, siliceous materials and other cementing materials and reinforced fibers as the main raw materials, through molding and high-pressure steam curing.

In terms of application, calcium silicate board for construction has the characteristics of light weight, non-combustibility, heat insulation, small dry and wet deformation and good processing performance, and can be used as composite wall panels and lightweight partition walls under various conditions. The board is especially suitable for the interior and exterior wall panels of composite walls, the partition wall panels of public buildings and civil buildings, as well as suspended ceilings and ceilings. Fiber-reinforced calcium silicate board has better moisture resistance, so it is also suitable for humid environments, such as bathrooms, kitchens, toilets and basements. At the same time, the fiber-reinforced calcium silicate board is also suitable for movable floors, and can be used in computer rooms, warehouses and warehouses with fire-proof and moisture-proof requirements.

(1) Bounce line: According to the floor elevation level, according to the ceiling elevation of the room design, the ceiling bottom elevation level is bombed along the walls around the wall, and the keel segment position line is drawn on the wall along the ceiling elevation level.

(2) Installation of hanging ribs: φ8 hanging ribs are selected for the hanging ribs, one end is welded with an L30*3*40 (long) angle steel sheet, and the other end is covered with a 50mm long screw thread, and fixed to the structural ceiling with a Ф8 expansion bolt. The spacing is 1200mm-1500mm, and the distance between the wall and the wall is 200-300mm. When the ventilation duct is large and the spacing requirement of the boom is exceeded, the angle steel frame is used as the main keel. The anti-rust paint must be painted before installing the hanging ribs.

(3) Installation of the main tee: The main tee is made of 38 light steel keel, with a spacing of 1200mm~1500mm. The pendants of the keel are used to connect with the hanging ribs during installation. The pendants must be fixed with the pipe thread of the boom, and the screw cap is required to exceed the wire. The rod is 10mm. The main keel must be pre-adjusted neatly and the elevation of the main keel must be adjusted by pulling the line, and the next process after the inspection is correct.

(4) Install the side keel: Fix the 25*25 paint keel with cement nails around the wall according to the elevation line on the wall, and the fixed distance is not more than 300mm. The wall putty leveling must be completed before installing the side keel.

(5) Install the secondary keel: According to the specifications and dimensions of the calcium silicate board, determine the T-shaped secondary keel spacing to be 600mm. When the length of the secondary keel needs to be extended by multiple continuations, use the secondary keel connector to connect the opposite ends while hanging the secondary keel and the connection points of the adjacent secondary keels should be staggered with each other. When installing the secondary keel, the clip should be firmly connected to the main keel, and the secondary keel must be excessively leveled at the intersection of the cross, and there should be no misalignment or large gaps.

(6) Install calcium silicate board: 600*600*15mm semi-embedded board or other methods are often used for calcium silicate board. When installing the ceiling, install it in order. It is strictly forbidden to install and unload. Do not pollute the cover panel during installation.

(7) Cleaning: After the calcium silicate board is installed, wipe the surface of the board with a cloth, and there should be no dirt or fingerprints.